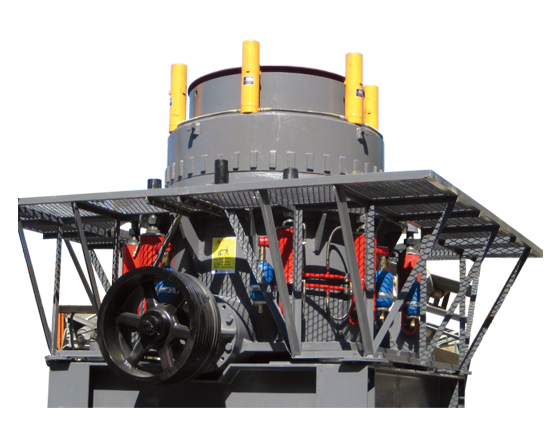

CONE CRUSHER

Leading The Way With New Technology

Cone crusher (Spring type)

- Strong impact pressure can create a higher crushing effect.

- Distributor at the top of machine can adjust the regular supply and the amount of distribution.

- Strong main body of machine supported by a block type of spring can guarantee accurate crushing and consistent particle sizes.

- Low height of machine and simple main body structure can facilitate machine installation, operation, repair and maintenance.

- No trivial malfunctions leads to low costs.

- Wide range of same types of machine available for easy part delivery and easy repair of trivial malfunctions

| Model No. | Feed Opening | Approx. capacity (t/h) | Power (Kw) | Pulley (rpm) | Approx weight (ton) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Closed (mm) | Open (mm) | 4 | 6 | 10 | 13 | 16 | 20 | 25 | 30 | 40 | 50 | 60 | ||||

| WCSH-900 | 80 | 70 | 27 | 48 | 57 | 65 | 80 | 37-55 | 630 | 12 | ||||||

| WCF-900 | 90 | 105 | 37 | 45 | 55 | 70 | 80 | |||||||||

| WCC-900 | 124 | 140 | 45 | 50 | 70 | 80 | 90 | 105 | ||||||||

| WCSH-1200 | 70 | 11 | 70 | 90 | 110 | 135 | 75-110 | 530 | 24 | |||||||

| WCF-1200 | 120 | 140 | 55 | 72 | 90 | 110 | 135 | 155 | 185 | |||||||

| WCC-1200 | 120 | 190 | 72 | 90 | 110 | 135 | 155 | 185 | 200 | |||||||

| WCSH-1300 | 75 | 100 | 82 | 110 | 130 | 160 | 215 | 95-130 (130-160) |

530 | 28.5 | ||||||

| WCF-1300 | 130 | 150 | 90 | 110 | 130 | 160 | 180 | 215 | ||||||||

| WCC-1300 | 180 | 200 | 110 | 130 | 160 | 180 | 215 | 230 | ||||||||

| WCSH-1680 | 100 | 140 | 125 | 160 | 190 | 225 | 150-190 | 510 | 49 | |||||||

| WCF-1680 | 170 | 200 | 145 | 190 | 250 | 290 | 335 | |||||||||

| WCC-1680 | 235 | 265 | 190 | 250 | 290 | 335 | 390 | 410 | ||||||||

| WCSH-2100 | 130 | 180 | 220 | 280 | 330 | 390 | 450 | 200-300 | 435 | 79 | ||||||

| WCF-2100 | 210 | 245 | 280 | 360 | 430 | 560 | 700 | 800 | ||||||||

| WCC-2100 | 300 | 335 | 360 | 430 | 560 | 700 | 800 | |||||||||

Machine capacity is based on general lime stone not wet or being rock containing moisture.

Hydraulic type of cone crusher

- Can prevent clogging of the crushing room due to broken steel pieces.

- High speed rotation can improve the productivity by at least 20%.

- Minimal setting of 8mm accuracy suitable for the sand production.

- Technical expertise cannot be mimicked, or machine ability cannot be followed.

| Model No. | Feed Opening | Approx. capacity (t/h) | Power (Kw) | Pulley (rpm) | Approx weight (ton) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Closed (mm) | Open (mm) | 4 | 6 | 10 | 13 | 16 | 20 | 25 | 30 | 40 | 50 | 60 | ||||

| WCC-900 | 125 | 140 | 30 | 52 | 49 | 54 | 7 | 86 | 97 | 113 | 37-55 | 650 | 11 | |||

| WCSH-900 | 20 | 70 | 30 | 52 | 62 | 70 | 86 | 86 | 97 | 113 | ||||||

| WCC-1200 | 170 | 190 | 76 | 79 | 97 | 119 | 146 | 167 | 200 | 216 | 75-110 | 550 | 22 | |||

| WCSH-1200 | 70 | 100 | 76 | 97 | 119 | 146 | 146 | 167 | 200 | 216 | ||||||

| WCC-1300 | 180 | 200 | 89 | 119 | 119 | 140 | 173 | 194 | 232 | 248 | 95-130 (130-160) |

550 | 26 | |||

| WCSH-1300 | 75 | 100 | 89 | 119 | 140 | 173 | 173 | 194 | 232 | 248 | ||||||

| WCC-1500 | 210 | 235 | 108 | 140 | 173 | 173 | 216 | 248 | 292 | 324 | 130-150 | 530 | 32 | |||

| WCSH-1500 | 90 | 100 | 108 | 140 | 173 | 250 | 216 | 248 | 292 | 324 | ||||||

| WCC-1680 | 235 | 265 | 135 | 173 | 205 | 205 | 270 | 313 | 605 | 756 | 443 | 150-190 | 530 | 48 | ||

| WCSH-1680 | 100 | 140 | 135 | 173 | 205 | 243 | 270 | 313 | 605 | 756 | 443 | |||||

| WCC-2100 | 300 | 335 | 238 | 302 | 356 | 421 | 389 | 464 | 605 | 756 | 864 | 200-300 | 450 | 75 | ||

| WCSH-2100 | 130 | 180 | 238 | 302 | 356 | 421 | 496 | 464 | 605 | 756 | 864 | |||||

Cone crusher (FSC type)

- Even when setting the mantle with lots of movement and low slope, it can help ensuring stable mutual crushing of particles.

- It is also simple to adjust the setting with complete hydraulic devices (option).

- Strong release spring maintains the setting to help maintaining the product particle size with consistency.

- Consistent fuel supply by the distributor and the rotation structure of the concave can prevent irregular abrasion on the mantle concave.

- Excellent lubrication device can guarantee a safe start-off.

- Simple structure design can facilitate maintenance, repair and management.

- Small size of parts to be worn off, thus it is possible to reduce the part costs.

| Model name | Max injection specs(mm) | Motor | Aggregate crushing ability (The capacity of crushing, t/h) | Crushing production ability (Sand capacity, t/h) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Exit setting interval (Discharge setting gap, mm) | By product specs (Sand size, mm) | ||||||||||||||||||

| 6 | 7 | 8 | 9 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 5 | 4 | 3.5 | 3 | 2.5 | |||

| WFSC-900 | 30x45x60 | 75 | 34 | 38 | 42 | 46 | 50 | 57 | 24 | 19 | 17 | 14 | 12 | ||||||

| WFSC-1300 | 40x60x75 | 175 | 82 | 90 | 96 | 108 | 120 | 131 | 44 | 35 | 30 | 26 | 22 | ||||||

| WFSC-1680 | 50x75x95 | 220 | 162 | 184 | 204 | 223 | 241 | 259 | 276 | 292 | 58 | 47 | 44 | 39 | 34 | ||||

| WFSC-2100 | 60x90x120 | 350 | 300 | 328 | 354 | 380 | 405 | 429 | 84 | 71 | 64 | 57 | 49 | ||||||