사업분야

사업분야

BUSINESS

Leading The Way With New Technology

Wet type

Dewatering screen and cyclone system

- 1. High efficiency dewatering screen makes sure the product is immediately dried free of water, thus it can be loaded right now.

- 2. Strong vibration motor can adjust the width of vibration depending on the particle size.

- 3. Highly anti-abrasion polyurethane screen net is applied to minimize the rate of abrasion.

- 4. After passing the dewatering screen or classifier, fine particles go through the cyclone to make perfect quality sands without any sludges of less than 200 meshes.

- 5. With internal quantity control, the classification point for the cyclone can be adjusted from 100 to 200.

| Model | Capa (t/h) | Using water (t/h) | Pump | Dewatering screen size | Power(kw) |

|---|---|---|---|---|---|

| WFS-130 | 130 | 100 | 6/4 | 2000x3000 | 55 |

| WFS-200 | 200 | 200 | 8/6 | 1500x3600 | 75 |

| WFS-250 | 250 | 300 | 8/6 | 1800x3900 | 75 |

| WFS-300 | 300 | 400 | 10/8 | 2100x4500 | 90 |

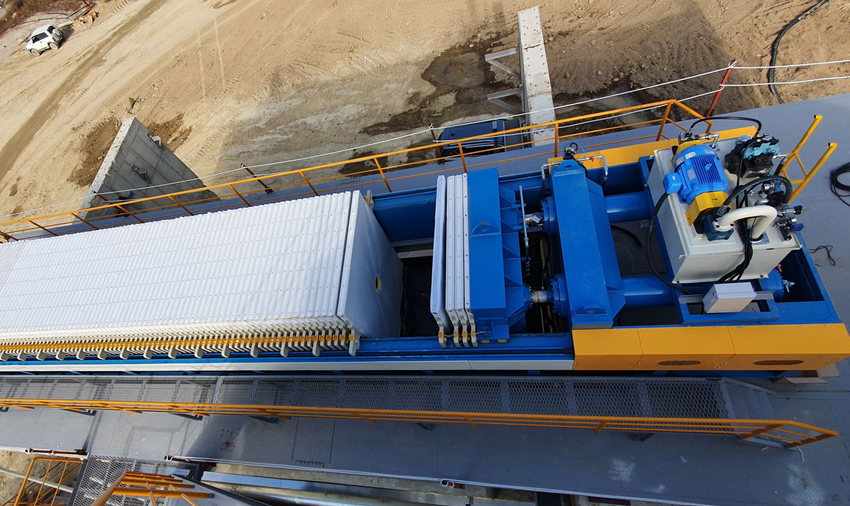

Waste water treatment and filter press

- 1.Scrapper automatically adjusted for the filter press condition is used in this sludge condensation system.

- 2. With self protection ability, when the large quantity sludge enters the system, the scrapper will automatically emerge to the top.

- 3. Use of minimal condensator, it shows low costs and suitability for repair and maintenance.